It is obvious for you to make up your mind to buy a 3D printer after hearing about the versatility of this machine. If, before the invention of 3D printers, one were to discuss the idea of a single machine which can build a custom phone case as well as musical instrument to any layman, the title of being in one’s own fancy would have been associated with the idea-giver’s name. But, today, we know that there exists such a machine that can be used for manufacturing most of the things that you see around yourself.

Trading of 3D printers is a billion dollar market for a few years now. And its growth is increasing significantly. There are a lot of 3D printers available in the market today that have different ranges of specifications catering to different demands. Hence it becomes important for you to look into the technicalities about 3D printing before buying yourself, your first 3D printer. Often you end up buying on impulse after being impressed by something’s appearance, price or just a friend’s recommendation. But the chances of such an impulse leading to regret after buying, is very high!

Link: link; Source: pick3dprinter

To ensure you do not regret the 3D printer that you buy, you need to hold on a little more on your impulse and read the complete article that delivers to you the tips you need for buying your very first 3D printer.

Tip 1: Research all the nine different types of 3D printing technologies

Link: link; Source: pick3dprinter

At least at the time of writing, the count is to nine! Not all of them are suitable for all kinds of use. If you need a 3D printer for printing objects that can be useful for your home or school, university, recommendations from experts are a certain set of printers based on a certain set of 3D printing technologies. Whereas, if your need is as a small manufacturer or a professional 3D designer, printer of parts and functional prototypes, the recommendations change. All in all, they will always be from nine different types of 3D printers based on;

- Fused Deposition Modeling (FDM).

- Stereolithography (SLA).

- Selective Laser Melting (SLM).

- Selective Laser Sintering (SLS).

- Digital Light Processing (DLP).

- Material Jetting (MJ).

- Binder Jetting (BJ).

- Laminated Object Manufacturing (LOM).

- Electron Beam Melting (EBM).

The two most favorable 3D printers for home use are based on FDM and SLA 3D printing technology. If you wish to use the 3D printer for manufacturing purposes, currently the most trending ones are based on SLS, MJ, or BJ 3D printing technologies. SLM, DLP and EBM 3D printers are used by professional 3D designers. Lastly, LOM is a simple technique favored by experts in the field for its sustainability and simplicity.

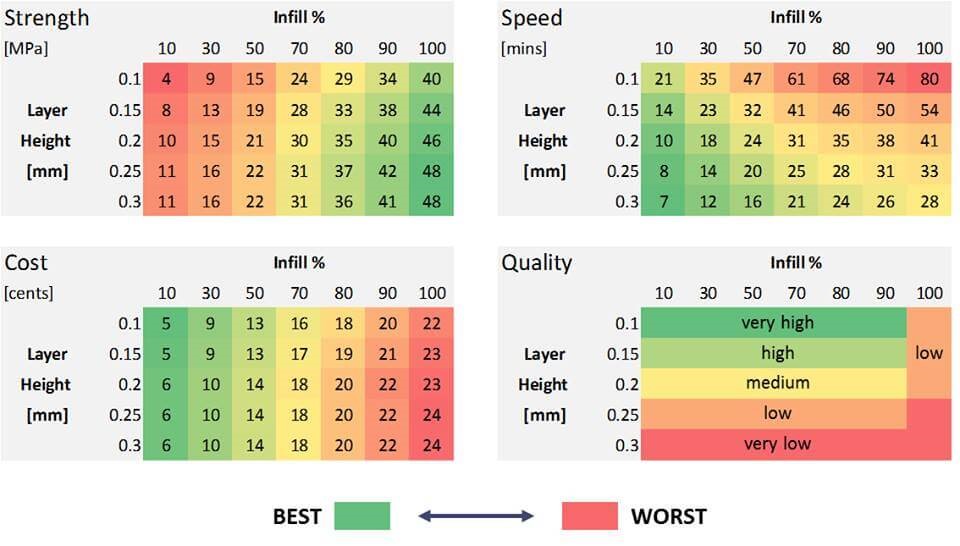

Tip 2: Associate your product goals with Print Speed and Layer Height or Print Resolution of the 3D printer

Link: link; Source: 3dprinterchat

If there are top two things that you ought to look in a 3D printer after knowing the technology on which it is based, they are: a) Layer Height/Print Resolution, and b) Print Speed. As you can guess by their terminologies, they are just like the quality and speed of any manufacturing technology. Here’s where you need to associate these two factors with the budget of the printer to ensure not getting cheated.

For example; according to the current trend of the market, a 3D printer costing around $500 to $700 would normally have the print speed in order of 20 mm per second to 80 mm per second and a layer height or print resolution of 0.1 mm to 0.4 mm. If this print resolution works for you, Pick3DPrinter has put up a list of the best cheap 3D Printers in the $500 range. For print resolution or layer height, you need to keep only one thing in your mind; the lower, the better. Whereas for print speed, the reverse holds true!

Tip 3: Search for the printer that is compatible printing with more materials and offers a larger build volume

Link: link; Source: pick3dprinter

The first part of this tip is gotta deal with the type of materials offered in the market to 3D print. Looking for a 3D printer that offers you printing with more 3D printing materials is always beneficial. At the end of the day, you don’t just wish to print a single kind of part and functional prototype with a single type of 3D printing material, yeah? Unless you are a manufacturer getting fixed orders! You want to play with ABS, PLA, PVA, TPU, metal powders, colorful resins and a lot more. So, if you are comparing the same budget, same print speed and layer height, look for a printer that supports printing with more materials.

Coming to the last part of the tip! It’s always more suiting to have a 3D printer that can build parts and functional prototypes of higher build volume. For a simple reason that, if it is able to do so with good quality, it will obviously be able to print smaller volumes with good quality.

The Conclusion

After knowing these tips, you can research your way out through the massive market of 3D printers. Overlooking them would end up into a selection that might not get you the desired results. 3D printers are the gift of additive manufacturing technology that is based on layer by layer creating concept. It’s meant to instill a lot of creativity, flexibility, and customization in a longstanding world of manufacturing technologies.

So, making the right choice is very much essential. Once you have done that, it will be easier to accomplish your jobs without hassle. There are so many things that you can do after getting a 3D printer at your home. You can 3D print toys for your kid, essentials for your home, start your own business in the field of 3D printing, learn designing, modeling, etc. Also 3D printing technology is termed as “the manufacturing technology of tomorrow” by experts. To make yourself part of such a technology is to foresee the future by putting a safe bet, so congratulations!